Jeremy Tew

Recycling Molybdenum: Turning Scraps into Sustainable Strength with Oryx Metals

Molybdenum, a versatile and resilient metal, plays a crucial role in our modern world. From fortifying steel for skyscrapers to powering high-efficiency electric vehicles, its applications are as diverse as they are essential. However, molybdenum is a finite resource, and with increasing demand, responsible management becomes paramount. Here's where molybdenum recycling steps in, transforming waste into valuable resources and creating a more sustainable future, with Oryx Metals at the forefront of these efforts.

The Power of Molybdenum: Why It Matters

Molybdenum boasts a unique set of properties that make it irreplaceable in various industries:

Strengthens Steel: When added to steel, molybdenum enhances its strength, toughness, and resistance to corrosion. This fortified steel is used in skyscrapers, bridges, pipelines, and countless other applications requiring exceptional durability.

High-Temperature Performance: Molybdenum maintains its strength and stability at high temperatures, making it ideal for components in jet engines, power plants, and other high-heat environments.

Electrical Conductivity: Molybdenum's ability to conduct electricity efficiently makes it valuable in electrical components and electrodes used in various industrial processes.

These characteristics solidify molybdenum's position as a critical building block for a strong and sustainable future.

The Challenge of Molybdenum Scarcity

While not as rare as some elements, molybdenum is a finite resource primarily extracted from molybdenum sulfide (MoS2) ores. The global demand for molybdenum is projected to rise significantly due to its increasing use in infrastructure development, green technologies like electric vehicles, and high-performance materials. This growing demand raises concerns about future availability and necessitates exploring sustainable solutions.

Unveiling the Potential of Molybdenum Scrap Recycling with Oryx Metals

Molybdenum recycling offers a compelling solution to address both resource scarcity and environmental impact. Oryx Metals is a leading player in this field, actively promoting and facilitating the responsible recycling of molybdenum scrap. Here's how it works:

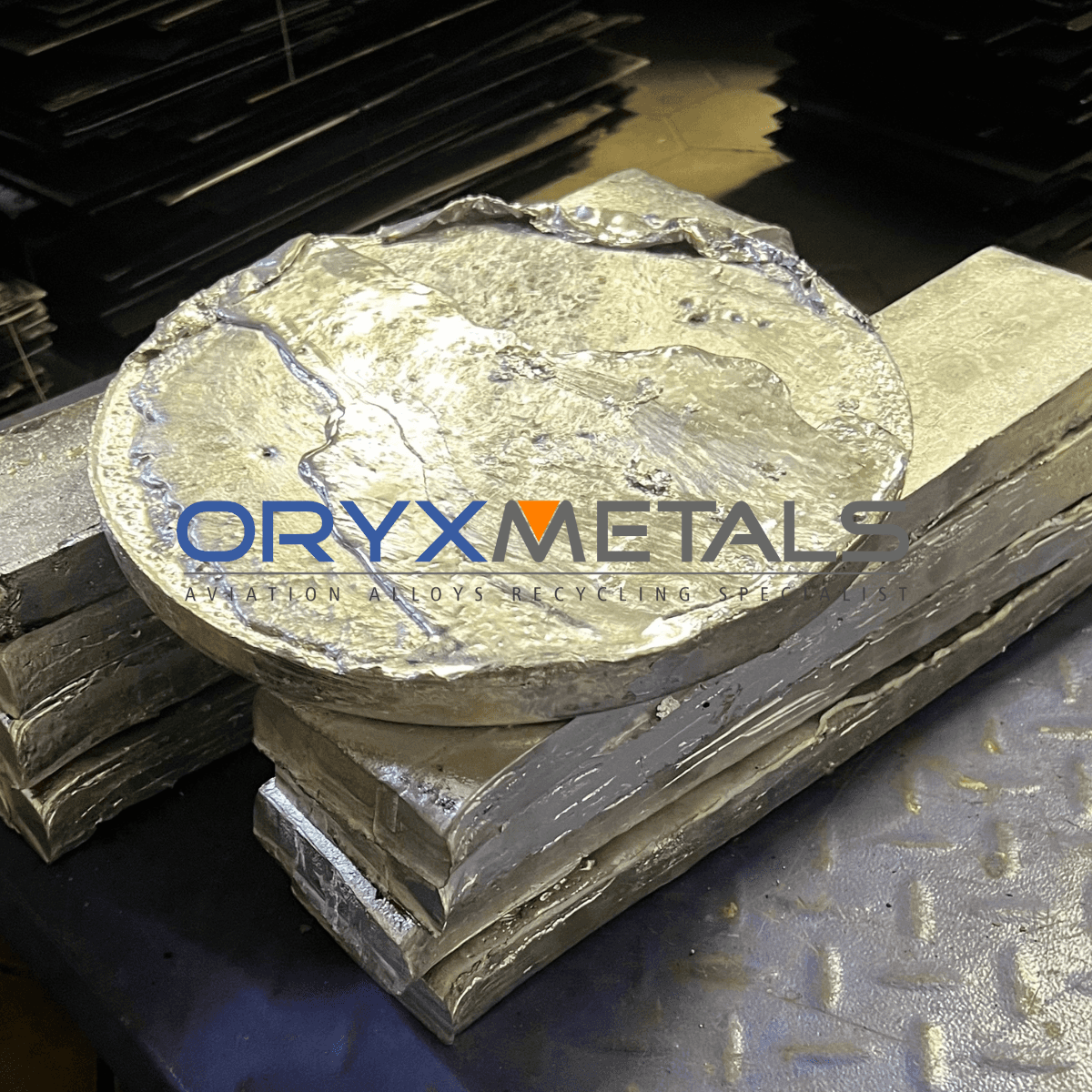

Molybdenum Solids and Turnings: Solid scrap molybdenum, such as offcuts or unused ingots generated during manufacturing processes, can be recycled and reintroduced into the production cycle. Oryx Metals offers efficient solutions for collecting and processing this valuable molybdenum scrap.

End-of-Life Products: Molybdenum-containing products like steel structures and used catalysts can be dismantled and recycled at the end of their lifespan. Oryx Metals works with partners throughout the supply chain to ensure these valuable molybdenum resources are recovered and reintroduced into the system.

The Many Benefits of Recycling Molybdenum Scrap

By effectively recycling molybdenum scrap, we can achieve several significant benefits:

Reduced Environmental Footprint: Recycling minimizes the need for virgin molybdenum extraction, lowering the environmental impact associated with mining activities such as land use, water pollution, and energy consumption.

Resource Conservation: Recycling conserves this valuable resource, ensuring its availability for future generations and fostering a circular economy where waste becomes a valuable resource.

Cost-Effectiveness: Recovered molybdenum from recycled materials can be a cost-effective alternative to virgin molybdenum, benefiting both manufacturers and consumers.

Energy Efficiency: Recycling molybdenum scrap often requires less energy than extracting and processing virgin ores, further reducing the overall environmental impact.

Building a Sustainable Future: The Road Ahead

Molybdenum recycling is still evolving, but it holds immense potential for a sustainable future. To unlock its full potential, we need to:

Invest in Research and Development: Advancements in recycling technologies and techniques can further improve efficiency and cost-effectiveness for processing molybdenum scrap.

Promote Responsible Waste Management: Encouraging responsible practices in manufacturing and product lifecycles can increase the availability of high-quality molybdenum scrap for recycling.

Develop Robust Infrastructure: Building and optimizing collection, sorting, and processing infrastructure is crucial for a well-functioning molybdenum recycling system.

A Shared Responsibility: Working Together

The success of molybdenum recycling hinges on a collaborative effort. Here's how different stakeholders can contribute:

Manufacturers: By implementing responsible waste management practices and exploring ways to design products for easier disassembly and recycling, manufacturers can significantly contribute to the molybdenum recycling loop.

Recycling Companies: Companies like Oryx Metals play a vital role by investing in advanced recycling technologies and infrastructure to efficiently process molybdenum scrap.

Policymakers: By creating regulations and incentives that encourage responsible molybdenum scrap recycling, policymakers can play a vital role in fostering a sustainable future for this critical resource.

By working together, we can transform molybdenum recycling into a cornerstone of a sustainable future. With Oryx Metals as your partner, you can be part of the solution. By giving new life to molybdenum scrap, we can ensure continued access to this vital resource while minimizing environmental impact and building a stronger, more resilient future for generations to come.

Contact us today:

To obtain pricing for your Molybdenum recyclable materials, please send photos and location information to sales@oryx-metals.com.