Jeremy Tew

Recycling Molybdenum and Vanadium Spent Catalyst: A Sustainable Approach with Oryx Metals

Catalysts containing Molybdenum (Mo) and Vanadium (V) play a crucial role in various industrial processes, particularly in the refining and chemical industries. However, these catalysts eventually lose their effectiveness and become spent. Rather than disposing of these valuable resources, recycling spent catalysts can recover significant amounts of Molybdenum and Vanadium, contributing to sustainability and resource efficiency.

The Value of Molybdenum and Vanadium in Spent Catalysts

Molybdenum and Vanadium are critical metals with unique properties that make them essential in many industrial applications. Molybdenum is known for its high strength, resistance to corrosion, and ability to withstand extreme temperatures, making it indispensable in the production of alloys, stainless steels, and as a catalyst in refining processes. Vanadium, on the other hand, is highly valued for its role in strengthening steel, its use in aerospace alloys, and its application as a catalyst in sulfuric acid production and other chemical processes.

Spent catalysts, while no longer effective for their original purpose, still contain substantial quantities of these metals. Recycling these catalysts not only prevents waste but also recovers valuable resources that can be reintroduced into the production cycle.

Oryx Metals: Leaders in Recycling Molybdenum and Vanadium Spent Catalysts

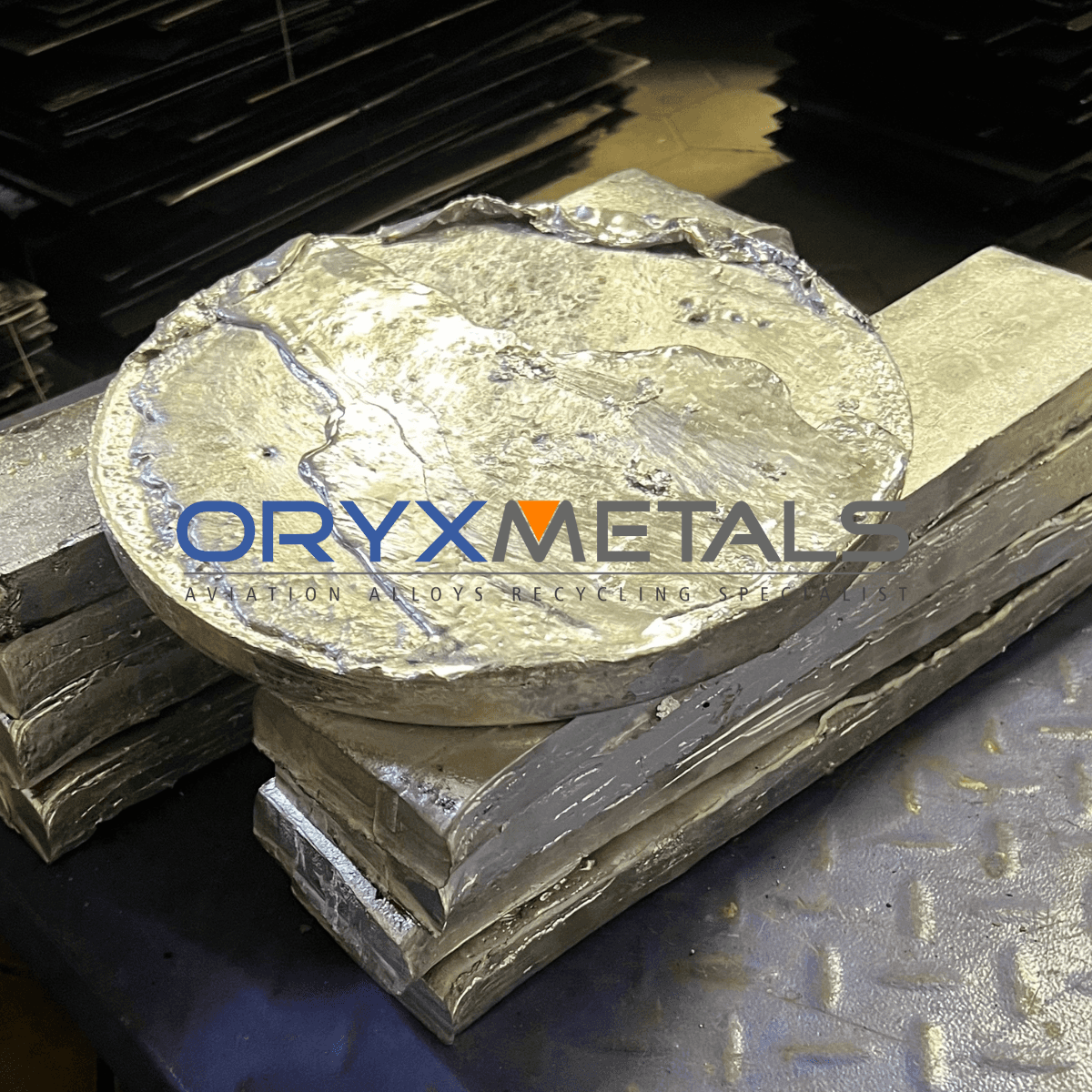

At Oryx Metals, we specialize in the recycling of spent catalysts containing Molybdenum and Vanadium. Our advanced processes are designed to maximize the recovery of these metals, ensuring that they are efficiently extracted and refined for reuse.

Why Recycle Spent Catalysts with Oryx Metals?

Maximizing Resource Recovery: Our recycling processes are optimized to extract the maximum amount of Molybdenum and Vanadium from spent catalysts, ensuring minimal waste and maximum resource efficiency.

Global Sourcing and Processing: We source spent catalysts from around the world and have the capability to process them in our state-of-the-art facilities, providing a seamless recycling solution no matter where your materials are located.

Environmental and Economic Benefits: Recycling spent catalysts reduces the need for mining new Molybdenum and Vanadium, thereby conserving natural resources and reducing the environmental impact of extraction. Additionally, it provides an economically viable alternative to purchasing virgin metals.

The Oryx Metals Process

Our recycling process begins with the collection and analysis of spent catalysts to determine their metal content. We then use advanced techniques to extract and refine the Molybdenum and Vanadium, ensuring that the recovered metals meet industry standards for reuse. This process not only helps to conserve natural resources but also supports a circular economy by reintroducing valuable materials into the supply chain.

Partner with Oryx Metals for Spent Catalyst Recycling

With decades of experience in the recycling industry, Oryx Metals is your trusted partner for recycling Molybdenum and Vanadium spent catalysts. Our commitment to sustainability, combined with our expertise in resource recovery, makes us the ideal choice for your recycling needs.

Contact us today to learn more about our spent catalyst recycling services and how we can help your business contribute to a more sustainable future. Visit our website at www.oryx-metals.com for more information.

Contact:

To obtain pricing for your Molybdenum (Moly) and/or Vanadium Spent Catalyst materials please contact our Commercial Team at:

Purchasing Click Here To Email